Main spindle drives

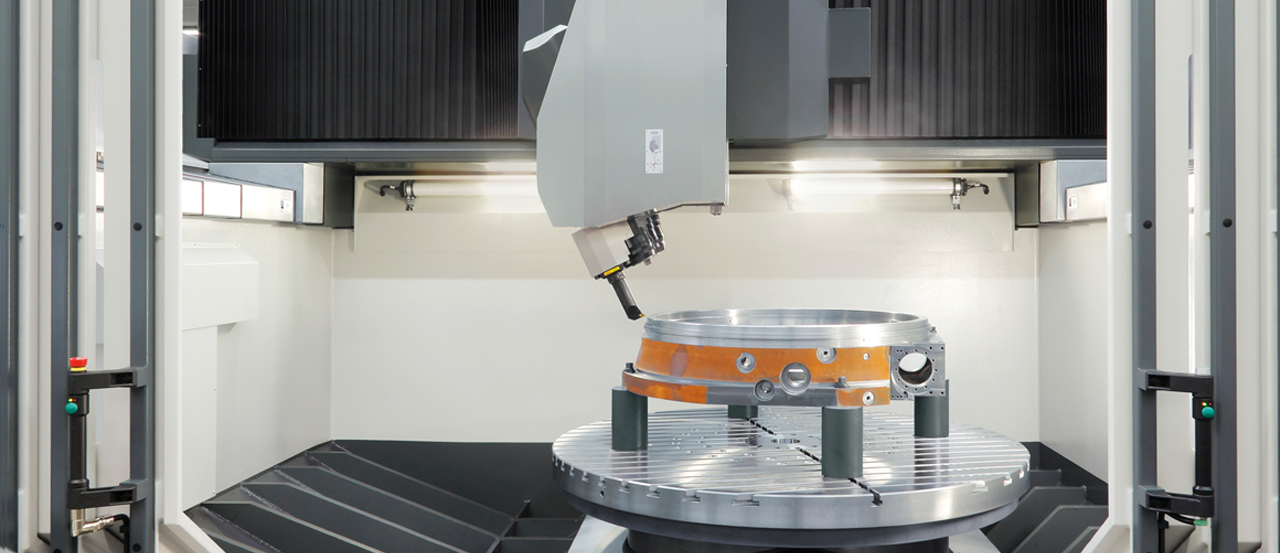

The main spindle makes up one of the most important components in a machine tool. It goes without saying that we design and manufacture these complex, electro-mechanical system components ourselves. The requirements placed on modern drives are extremely varied. We constantly strive to completely fulfil these wishes and demands. That requires continued and steady further development. We have been mastering this task successfully for decades.

Each spindle is intensively tested for performance and accuracy before use on our specially developed spindle test benches.

Design

Design

- Directly driven spindles, belt-driven spindles or gear-driven spindles as special solution

- Water or air cooled motors in asynchronous or synchronous design

- Various standard and special solutions of taper for the main spindle

SK 40, SK 50, BT 40, BT 50, HSK A63, HSK A100, C6, C8 - Combined milling and drilling processing by additionally placed steel turning tool holder on the main spindle

- Spindle adaption for support of angular heads and multi-spindle heads or fast turning spindles by simple torque support or threepoint support

Benefits

Benefits

- Directly driven spindles, belt-driven spindles or gear-driven spindles as special solution

- Water or air cooled motors in asynchronous or synchronous design

- Various standard and special solutions of taper for the main spindle

SK 40, SK 50, BT 40, BT 50, HSK A63, HSK A100, C6, C8 - Combined milling and drilling processing by additionally placed steel turning tool holder on the main spindle

- Spindle adaption for support of angular heads and multi-spindle heads or fast turning spindles by simple torque support or threepoint support

Technical data

Technical data

For technical details as

- Drive type

- Max. torque

- Max. power

- Breakpoint speed

- Tool holding fixture

please click here.Spindle test benches

Spindle test benches

Each spindle is subjected to an intensive test before assembly. On our specially developed and constructed spindle test benches, they are brought up to maximum performance step by step in at least two test intervals of 8 hours each. Up to three spindles can run through the test phase in parallel. Only spindles with 100% performance are installed in our machines.

Product brochure

Product brochure

For more information about our original components please have a look at the broschure. Click here to open or download the brochure as pdf file.